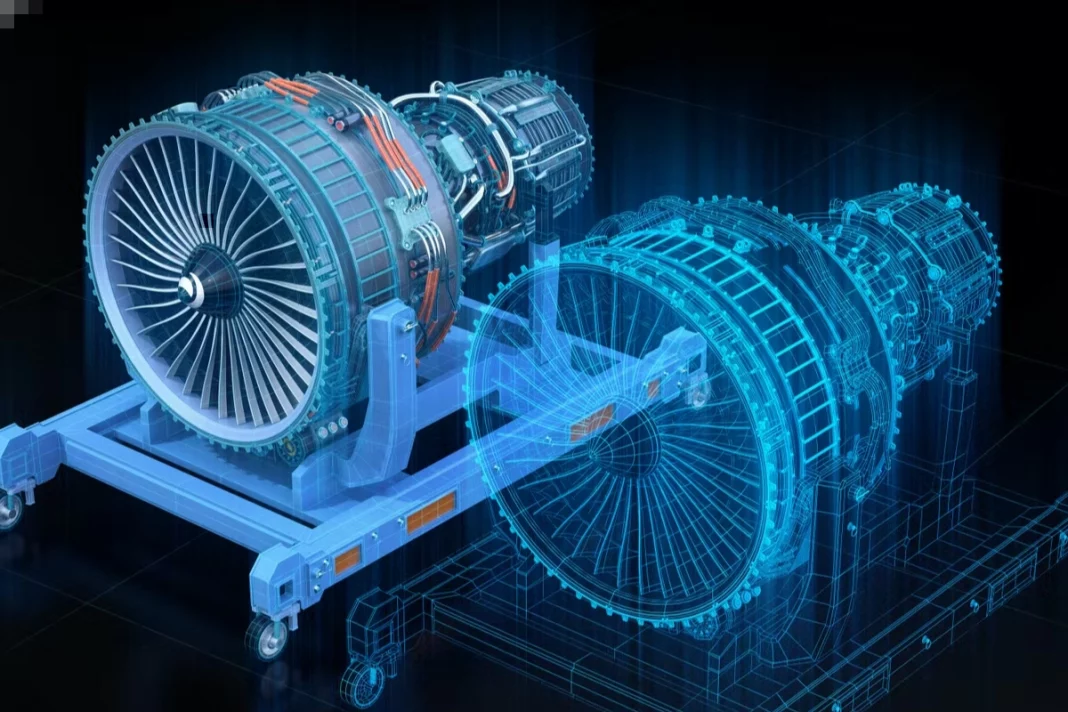

Digital Twin: A digital twin is an interactive virtual representation of a physical asset, procedure, system, or environment that resembles and functions exactly like its physical counterpart. In order to predict potential performance outcomes and challenges that the real-world product may experience, a digital twin ingests data and replicates procedures.

How does it work?

The strength of digital twins stems from their ability to better visualise real-world objects by linking them with real-world data. Cross-functional teams can design, develop, test, deploy, and run complex systems in a collaborative, immersive manner thanks to digital twins. They aid businesses in understanding the past, assessing the situation now, and avoiding issues in the future. They assist in decision-making through sales and marketing insights, analysis, 3D visualisation, modelling, and prediction.

How to create a digital twin?

To build digital twins, conceptual models are imported (through BIM, CAD, or GIS) or physical objects are scanned in the real world for visualisation and analysis with enterprise and Internet of Things (IoT) data. Real-time 3D, a computer graphics technology that creates interactive content more quickly than human perception, can power a digital twin that can filter, arrange, and present various data sources (both information and models) as realistic, interactive visualisations.

Digital twins are virtual depictions of the forces, interactions, and movements that assets may experience in the real world. This enables users to interact with three-dimensional, dynamic content that responds in real time to their actions. They may accurately mimic real-world situations, what-if scenarios, and any situation imaginable in this virtual environment, and instantaneously view the results on any platform, including mobile devices, computers, and augmented, mixed, and virtual reality (AR/MR/VR) devices.

Every deployment of a digital twin is different. Deployments frequently happen in stages, with the complexity and commercial effect increasing with each step. A digital twin is an exact depiction of a network or system that is as large as a city, with each of its components constantly linked to engineering, construction, and operating data.

Benefits of a digital twin?

Customers see increased data access immediately after digital twin implementations. Reduced maintenance costs, better-informed process modification decisions with significant potential savings, and increases in maintenance and operational efficiency are additional advantages as a digital twin evolves. Better designs from the outset are advantageous since 80–90% of the costs associated with building, operating, and maintaining a facility are decided upon during the design phase.

Digital twins have enhanced multiuser collaboration and communication in the design sector. Clients in the preconstruction phase benefit from seamless trade coordination and data aggregation.

Digital twin technology has enabled safety training, quality assurance, and quality control, all of which have considerably decreased accidents and mistakes in the construction sector. The advantages of using digital twin projects for maintenance and operations include streamlined operations, fewer downtime, and lower maintenance and staff expenses.

Making design, operation, and maintenance decisions is evolving as a result of real-time data interaction. Every physical location and asset on the world is being designed, constructed, and operated differently as a result of the ability to view and simulate complicated operations in real-time 3D.

Also Read: What is CHATGPT? The new technology developed by Open AI that everyone is talking about, all you must know

Keep watching our YouTube Channel ‘DNP INDIA’. Also, please subscribe and follow us on FACEBOOK, INSTAGRAM, and TWITTER